Let’s Build a Crane!

Bridge Cranes

When considering crane solutions, define the goal of your project to decide what configuration is best for you. Load size, span, speed, and service are just a few factors to consider when selecting a bridge crane.

Bridge Cranes: can accommodate lifting capacities and bridge spans depending on the requirements of the building structure.

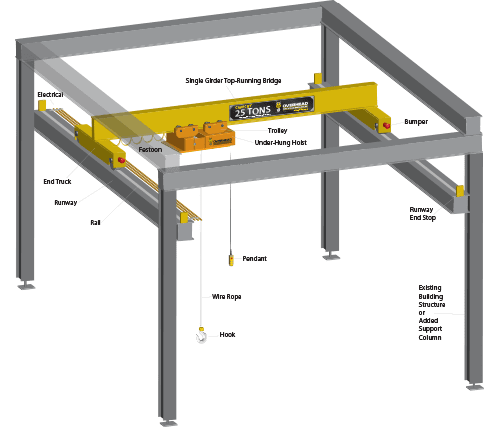

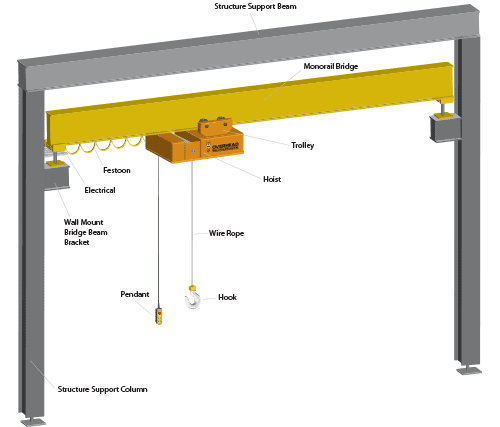

The image on the right shows a single girder, top-running bridge crane.

Top Running Cranes

With no limiting capacity (meaning they can be engineered for small or large loads), Top Running Cranes are supported by the building structure, runway or sister columns, running on rails located along the top of the structure. These cranes are ideal when there is plenty of ceiling clearance for the bridge to travel on top of a runway system.

They can be designed in single or double girder configurations.

| Single Girder | Double Girder |

|---|---|

| Lifting capacities less than 20 tons | Lifting capacities expected to exceed 10 tons |

| Bridge spans less than 60 feet | Bridge spans exceed 60 feet |

| Ideal in spaces with lower ceilings | Accommodates high hook lifting as the hook is able to go between the girders |

| Lower production cost | Can operate at faster speeds than single girder cranes |

| High Speed | Double girder cranes can utilize most of our accessories |

| Additional lift and speed |

Under Running Cranes

Built with support at the bottom of the runway beams, Under Running Crane wheels run along the bottom of the lower beam flange. Under-hung bridge cranes are ideal when low ceiling clearance prevents the bridge from traveling on top of the runway system. Designed for lower capacities, these cranes offer convenient features.

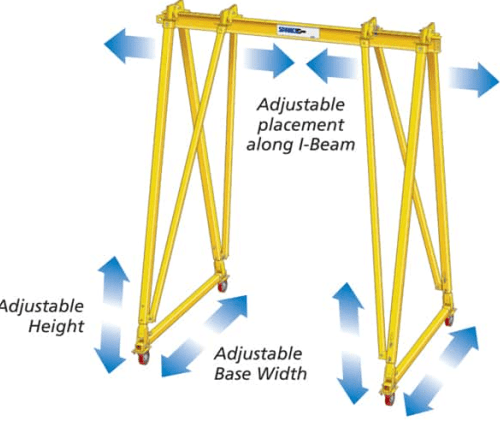

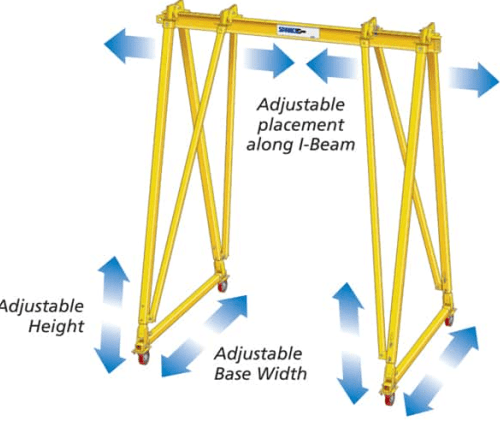

Gantry

Similar to the bridge crane, a Gantry crane runs on a track at the floor level, rather than suspended overhead. These cranes have legs that travel on rails embedded in–or on top of–the ground structure, or can travel on casters for easy movement when not being utilized. Quick and easy to assemble, portable designs available, and adjustable widths and heights are a convenient option.

This product is efficient and economical, often used for portable projects, outdoor applications, and quick services.

Gantry

Similar to the bridge crane, a Gantry crane runs on a track at the floor level, rather than suspended overhead. These cranes have legs that travel on rails embedded in–or on top of–the ground structure, or can travel on casters for easy movement when not being utilized. Quick and easy to assemble, portable designs are available and adjustable widths and heights are a convenient option.

This product is efficient and economical, often used for portable projects, outdoor applications, and quick services.

Monorail Cranes

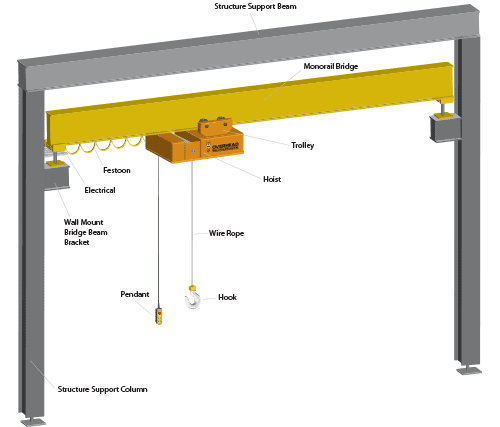

Monorail cranes are a common type of overhead crane consisting of a single beam and a hoist. The hoist/trolley runs on the bottom flange of the monorail beam, similar to how an underhung crane operates. Only two directions of hook travel are allowed by the monorail: up and down, and along the axis of the monorail beam.

This specialized type of overhead lifting system is very effective when properly designed into a factory layout. Monorail systems, by their nature, are most often integrated into continuous production systems for material transport; for example, hot metal operations in a foundry, paint booths, etc.

- Usually lift smaller loads with efficiency for maintenance applications.

- Can also be designed for curves, branches and switches, and with changes in elevation.

- Ideal when lifting and moving is limited to two axes versus three

Monorail Cranes

Monorail cranes are a common type of overhead crane consisting of a single beam and a hoist. The hoist/trolley runs on the bottom flange of the monorail beam, similar to how an underhung crane operates. Only two directions of hook travel are allowed by the monorail: up and down, and along the axis of the monorail beam.

This specialized type of overhead lifting system is very effective when properly designed into a factory layout. Monorail systems, by their nature, are most often integrated into continuous production systems for material transport; for example, hot metal operations in a foundry, paint booths, etc.

- Usually lift smaller loads with efficiency for maintenance applications.

- Can also be designed for curves, branches and switches, and with changes in elevation.

- Ideal when lifting and moving is limited to two axes versus three

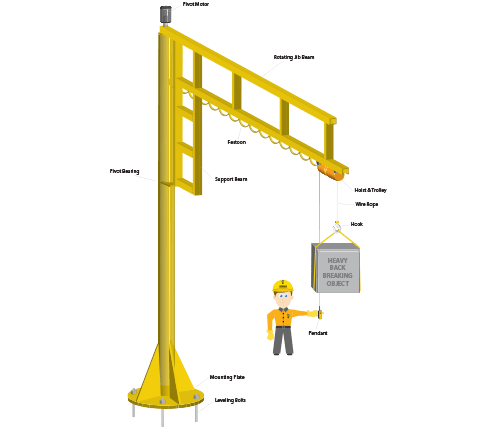

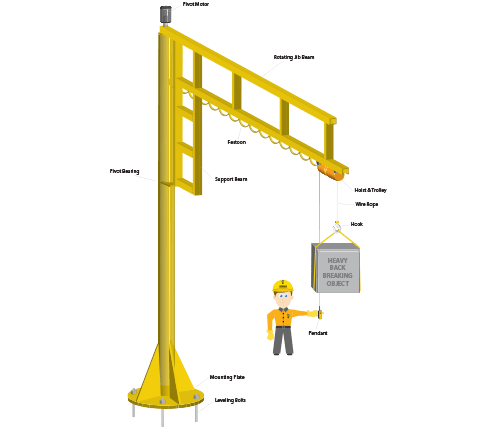

Jib Cranes

Jib Cranes are versatile, come in a variety of styles, and do not need a runway system. They can be designed to be stand-alone or mounted, and offer a wide range of capacities, heights, and spans. Jib cranes are durable, space-saving, and economical. They are ideal for jobs that require a smaller circular space, and typically offer 180°-360° rotation. The jib crane can also be motorized to provide precise spotting of loads.

Jib Cranes

Jib Cranes are versatile, come in a variety of styles, and do not need a runway system. They can be designed to be stand-alone or mounted, and offer a wide range of capacities, heights, and spans. Jib cranes are durable, space-saving, and economical. They are ideal for jobs that require a smaller circular space, and typically offer 180°-360° rotation. The jib crane can also be motorized to provide precise spotting of loads.

Workstation

Workstation Cranes are designed to allow operators a comfortable style of lifting or moving loads in a small area. Workstation cranes are lighter-duty systems and do not require an existing support structure for installation. These cranes have the ability to pivot 360 degrees, which allows them to cover a large space with a minimal footprint.

Standard support distances of 20, 25, and 30 feet.

Designed for repetitive lifting and positioning loads.

Benefits include increased production and efficiency

Ideal for shipping departments or machining stations where an operator would be required to repetitively lift and move a heavy object.

Workstation

Workstation Cranes are designed to allow operators a comfortable style of lifting or moving loads in a small area. Workstation cranes are lighter-duty systems and do not require an existing support structure for installation. These cranes have the ability to pivot 360 degrees, which allows them to cover a large space with a minimal footprint.

Standard support distances of 20, 25, and 30 feet.

Designed for repetitive lifting and positioning loads.

Benefits include increased production and efficiency.

Ideal for shipping departments or machining stations where an operator would be required to repetitively lift and move a heavy object.

Thern Davit

Engineered for heavy lifting and positioning,Thern Davit cranes offer a wide variety of portable and stationary lifting solutions.

Ideal for many applications, including theaters, wastewater treatment facilities, as well as large construction and manufacturing companies. We are a proud distributor of Thern Winches and Cranes.

Ask if Thern Davit rentals are an option for you

Thern Davit

Engineered for heavy lifting and positioning,Thern Davit cranes offer a wide variety of portable and stationary lifting solutions.

Ideal for many applications, including theaters, wastewater treatment facilities, as well as large construction and manufacturing companies. We are a proud distributor of Thern Winches and Cranes.

Ask if Thern Davit rentals are an option for you

Crane Hoist

We offer a wide range of hoists and many different brands, capacities and options. We are a authorized service provider for Jet hoists.

500lb to 50 ton Capacity

Hoist Types:

Electric or manual chain

Wire rope

Indoor/Outdoor

Hook or Trolley mounted

- Lifting capacity 1-75 TONS

- Wire Rope Hoists

- Explosion Proof

- Electric Chain Hoists

- Hand Hoists

- Corrosion Resistant

Crane Accessories

deb content coming

BELOW THE HOOK ATTACHEMNTS

- Building Assessments

- Patented Track Runways

- Column Runways

- Braceless Runways

- Tieback Runways

Crane Runways

DEB CONTENT COMING

fabricated in shop

- End Trucks

- Lifting Attachments

- Wire Rope

- Electric Chains

- Manual Chains

- Radio Controls

- Festoons

- Cables

Crane Accessories

deb content coming

BELOW THE HOOK ATTACHEMNTS

- Building Assessments

- Patented Track Runways

- Column Runways

- Braceless Runways

- Tieback Runways

COMPONENTS

Centrally located, our warehouse engineers, manufactures, and supplies a wide selection of crane and hoist replacement parts. Repairs and replacements can be installed immediately from our inventory, minimizing your down time and saving money overall.

Understanding the fundamental parts and types of our products may help decide what crane or hoist solution is best for your business. OHCSI offers a wide range of brands, capacities and options.

Learn more about our crane components:

COMPONENTS

Centrally located, our warehouse engineers, manufactures, and supplies a wide selection of crane and hoist replacement parts. Repairs and replacements can be installed immediately from our inventory, minimizing your down time and saving money overall.

Understanding the fundamental parts and types of our products may help decide what crane or hoist solution is best for your business. OHCSI offers a wide range of brands, capacities and options.

Learn more about our crane components:

Using wire rope or a chain, the hoist lifts, holds, lowers, or moves large capacities to increase workflow and efficiency. We are an authorized service provider for a variety of reputable hoists, including Jet Hoists, that include a 50-ton capacity. We also feature:

- Electric or manual chain hoists

- Wire rope hoists

- Explosion Proof

- Corrosion Resistant

- Indoor/Outdoor

- Hook or Trolley mounted

Usually part of the building structure, a runway allows the bridge to move up and down the bays.

We will custom fabricate a runway system to meet your specific needs. Our overhead crane specialists have over 20 years of experience in designing runway systems that are safe and maximize efficiency. We will evaluate if you need a freestanding runway, or runway that is built utilizing the existing building structure. We consider how many cranes you are needing to operate on the runway and their lifting capacities. Whether you need a new runway system, or a modification to an existing system, you can be confident that we have the resources to meet your needs.

- Building Assessments

- Patented Track Runways

- Column Runways

- Braceless Runways

- Tieback Runways

Configured to meet your specific needs, a trolley supports the hoist, moving along the bridge to position the hoist and hook for your production or manufacturing specifications.

Connected to a hoist, a hook supports the lifted load.

Made of one or two beams (a single or double girder design), the bridge is the primary structure that connects the runway and moves the hoist using a trolley.

Permanent or mobile, tracks supported by a runway rail allow the crane to travel easily.

Configured on either side of a bridge, end trucks move the bridge up and down the railway.

With many attachment options, bumpers are made to absorb energy and minimize impact at the end of transport.

Mounted on a panel, controls allow the operator to drive and control a hoist with speed and accuracy.

Experienced. Durable. Trustworthy.

Can we help decide?

Contact us for a quote to find what overhead crane would meet your needs.